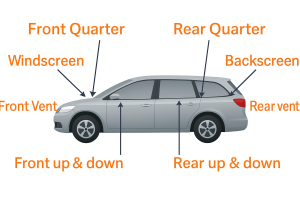

Side & Rear Autoglass Replacement – Noosa & Sunshine Coast

Insurance claims for side and rear auto glass replacement can be organized and processed on our customer’s behalf.

To produce a tempered glass for automobiles, glass is heated until its temperature gets near the softening point and then cooled quickly to get the surface of glass to produce prestress layer on the surface of glass and produce tensile stress inside it, so as to improve the strength of glass.

The heating cycle is also used to shape or curve the glass, either by allowing the heated glass to ‘sag’ to a pre-defined mould shape under gravity, or for more complex shapes, by being pressed to shape by male and female moulds.

Characteristics:

Enhanced Safety

Tempered glass is engineered to shatter into small, blunt pieces, minimizing the risk of injury in the event of breakage. This safety feature is crucial for protecting passengers during accidents.

Superior Strength

With impact resistance five to eight times greater than standard glass, tempered glass offers unmatched durability, making it ideal for vehicle windows that face daily wear and tear.

Thermal Stability

Capable of withstanding temperatures from 250°C to 350°C, tempered glass maintains its integrity under extreme conditions, ensuring reliable performance in all climates.

Colour Tint

Available in various tints and finishes, tempered glass can be tailored to meet specific aesthetic and functional needs, including solar absorption and acoustic properties.

Features

Some vehicles may require Solar absorbing, Acoustic or Heater demist glass. Low visible Compliance Mark for vintage and collectable cars.